Softwoods

Learn More

Balsa wood is famous for being one of the lightest commercial woods in the world, yet it offers surprising strength and versatility. From early river rafts in the Americas to today’s model aircraft, surfboards, and high-tech composite panels, balsa has earned a permanent place in woodworking and engineering. This article looks at the origin and history of balsa, how and where the trees grow, the appearance and properties of the wood, and the many uses of balsawood in crafts, packaging, insulation, and beyond.

Balsa wood comes from the tree Ochroma pyramidale, native to tropical Central and South America, from southern Mexico down through Ecuador, Peru, Brazil, and Bolivia. The Spanish word “balsa” means “raft,” a reference to the lightweight rafts made by Indigenous peoples using balsa logs to navigate fast rivers and coastal waters.

When European explorers reached the Americas in the 16th century, they quickly noticed how incredibly light these timber logs were. Over time, interest in balsa spread and the wood began to be exported for use in life rafts, early aircraft, and specialty applications where low weight mattered. During World War II, balsa was used extensively in aircraft construction and life preservers, cementing its reputation as the go-to lightweight wood.

Today, plantation-grown balsa is harvested and shipped around the world. It remains a staple in model building, prototype construction, and core material for composite panels used in boats, wind-turbine blades, and specialty wood products.

In nature, balsa trees flourish in humid tropical and subtropical climates with plentiful rainfall and well-drained soils. They often colonize disturbed sites such as landslides, riverbanks, and forest gaps, taking advantage of full sun and rich, freshly exposed soil. Balsa is considered a pioneer species: it grows very quickly, stabilizes the soil, and helps shade and shelter slower-growing rainforest trees.

Balsa trees grow at elevations up to about 1,000 meters (≈3,280 ft) above sea level. Under good conditions they can reach 30 m (98 ft) or more in height in only 10–15 years, with trunk diameters of 60–90 cm (24–35 in). Most commercial plantations harvest trees around 6–12 years of age, when the balance between rapid growth and usable density is ideal.

Interestingly, even though balsa is one of the softest woods in the lumber yard, it is botanically a hardwood because it comes from a broadleaf, flowering tree rather than a conifer. On Tree Plantation it often appears alongside other tropical hardwood trees such as mahogany and teak, but its working properties are very different.

Balsa is widely recognized as the lightest commercial wood available. Its density can vary significantly within the same log, depending on age, growth rate, and plantation conditions. Lumber is therefore graded by density so that builders can match the right board to the right use—ultra-light pieces for model aircraft wings, denser pieces for high-stress parts and end-grain core blocks.

Despite its low density, balsa has a high strength-to-weight ratio. The wood consists of large, thin-walled cells filled mostly with air. When loaded properly—especially as end-grain in sandwich panels—it can carry impressive loads for its weight. This makes it valuable any time designers need stiffness and buoyancy without adding bulk.

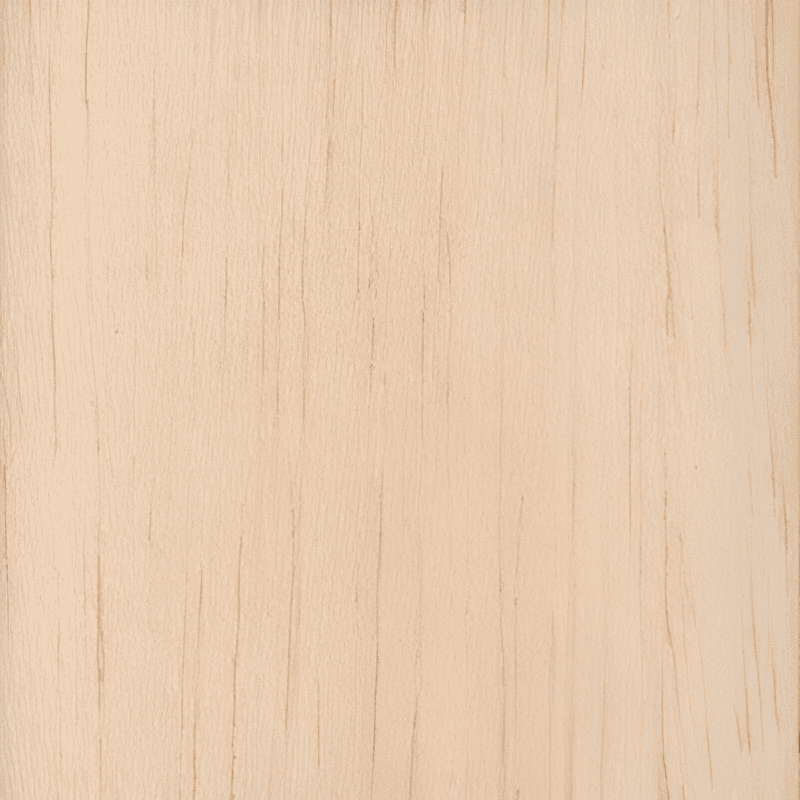

In appearance, balsa ranges from pale cream to almost white, sometimes with subtle pink or yellow tones. The texture is fine and uniform, and the grain is generally straight. These qualities make the wood easy to cut, carve, sand, and glue, which is why it is a staple in hobby shops and model-building kits. Its softness does mean it dents easily, so many projects use sealers, laminates, or fiberglass skins to protect the surface from wear.

The same qualities that make balsa so interesting in the forest—rapid growth and airy wood— make it extremely useful once milled. Some of the most common balsa wood applications include:

Turning a tall, tropical tree into clean, straight pieces of hobby wood or structural core material involves several steps:

1. Harvesting: Foresters select mature balsa trees in plantations or managed forests, often focusing on straight trunks with good diameter and minimal defect. Responsible producers follow sustainable forestry guidelines to protect soil, water, and surrounding biodiversity.

2. Debarking and sectioning: Once felled, the logs are debarked and cut into manageable sections. Removing bark early helps reduce pests and decay.

3. Sawing and block cutting: Logs are sawn into flitches, boards, or blocks depending on the final use. Core manufacturers often cut end-grain blocks for composite panels, while hobby wood is sawn into thin sheets and strips.

4. Drying: Because balsa holds a lot of moisture, controlled drying is critical. The wood is air-dried and/or kiln-dried to reach a stable moisture content, improving dimensional stability and strength.

5. Grading and sorting: Once dry, balsa is graded by density, color, and appearance. Light, medium, and heavy grades are sorted for different markets—model builders want very light stock, while structural users may specify denser core material.

6. Final processing: Boards are planed, sanded, and cut into specific sizes, such as hobby sticks, sheets, or core panels. Some material is laminated with veneers, fiberglass, or other skins for specialty products.

In parts of Central and South America, Indigenous communities have used different parts of the balsa tree in traditional medicine. Bark preparations have been used for their anti-inflammatory and analgesic effects, sometimes taken as a tea for fever, headaches, and rheumatic pain. Leaf poultices have been applied to minor wounds, bites, and skin irritations.

These practices are based on long-standing local knowledge rather than modern clinical trials, but they reflect the broader cultural and ecological value of the species. As with many medicinal plants featured on Tree Plantation, balsa reminds us that trees can be important not only for timber, but also for traditional health and forest-based remedies.

Because balsa is a true tropical species, it grows naturally in warm, humid regions that never experience frost. Many Caribbean islands have climates suitable for small-scale planting, especially where rainfall is reliable and soils are deep and well-drained. In the United States, outdoor cultivation is mostly limited to southern Florida, Hawaii, and a few frost-free microclimates.

Balsa trees need consistently warm temperatures, abundant moisture, and protection from strong, drying winds. Where those conditions are met, they can be integrated into agroforestry systems as fast-growing shade and biomass trees, or managed plantation blocks for future timber. In cooler or drier regions, balsa is not practical as an outdoor tree, so most users rely on imported lumber instead.

In short, balsa wood’s unique combination of light weight, strength, and easy workability has kept it in demand for more than a century. From river rafts and surfboards to model aircraft, insulation, and high-tech composite cores, this remarkable tropical hardwood continues to offer creative possibilities to builders, engineers, and hobbyists around the world.

Balsa wood comes from Ochroma pyramidale, a tree with very large, thin-walled cells packed with air. This gives balsa an extremely low density compared to most hardwoods, yet its cellular structure still provides good stiffness. When used correctly—especially as end-grain balsa in sandwich panels—its strength-to-weight ratio is excellent for model aircraft, marine cores, and composite structures.

The best-known use is model building—from model airplanes and boats to architectural mockups. Because it is buoyant and easy to shape, balsa is also used in surfboards and paddleboard cores, lightweight craft projects, and as shock-absorbing packaging for delicate items. In industry, end-grain balsa is widely used as a composite core material in marine, transportation, and wind-energy panels.

Commercial balsa is usually sold by density, typically ranging from about 80–240 kg/m³ (5–15 lb/ft³). Lighter grades are favored for weight-critical parts in RC model aircraft and gliders, while medium and higher densities are chosen for structural components and end-grain core blocks. When selecting balsa, match the density to the stiffness and impact resistance your project requires.

Yes—when it comes from responsibly managed plantations. Balsa is fast-growing and can reach harvestable size in just a few years, which makes it a renewable resource compared to slower-growing tropical hardwoods. Look for suppliers who can document sustainable forestry practices or third-party certification to ensure traceability for marine, aerospace, and biomass/composite applications.

Because balsa is very soft and porous, it benefits from sealing and reinforcement. Many builders apply a sanding sealer or thinned lacquer first, then finish with polyurethane, epoxy, or lightweight film coverings. For structural parts, balsa can be laminated with fiberglass, carbon fiber, or paper veneers to dramatically increase stiffness and durability. Always use sharp blades and pre-seal edges to reduce fuzzing and tear-out.

Balsa is much lighter and easier to cut, so it is ideal for weight-sensitive structures like wings, tail surfaces, and fuselage frames. Basswood (linden), by contrast, is denser and stronger with a finer grain, making it better suited for carving, detailed parts, and components that need crisp edges or extra durability. Many model builders combine both: balsa for main framing and basswood for reinforcement, mounts, and high-stress areas.

Balsa trees are native to Central and South America, from southern Mexico through Ecuador, Peru, and Brazil. They prefer warm, humid climates with well-drained soils. Outside the tropics they are difficult to grow, but small-scale plantings may succeed in frost-free, subtropical areas like parts of southern Florida, Hawaii, and the Caribbean, provided they have ample rainfall and protection from cold.

Yes. The same low density that makes balsa so light also provides thermal and acoustic insulation benefits. Its porous structure traps air, helping to dampen sound and slow heat transfer. While it is not as common as synthetic insulation products, balsa can be used in specialty insulated panels, refrigerated transport, and other high-performance applications where a natural, lightweight core is desirable.

In parts of Central and South America, indigenous communities have used balsa bark and leaves in traditional medicine. Bark infusions have been employed for their anti-inflammatory and analgesic effects, while leaf poultices are sometimes applied to minor wounds or skin irritations. These uses are based on folk knowledge and are not a substitute for modern medical care, but they highlight the tree’s broader cultural importance.

Copyright © All rights reserved Tree Plantation